This project explores Kolon One and Only Tower, Seoul designed by Morphosis Architects. The project was to understand the building in all its tectonic parts; design, structure, and materials.

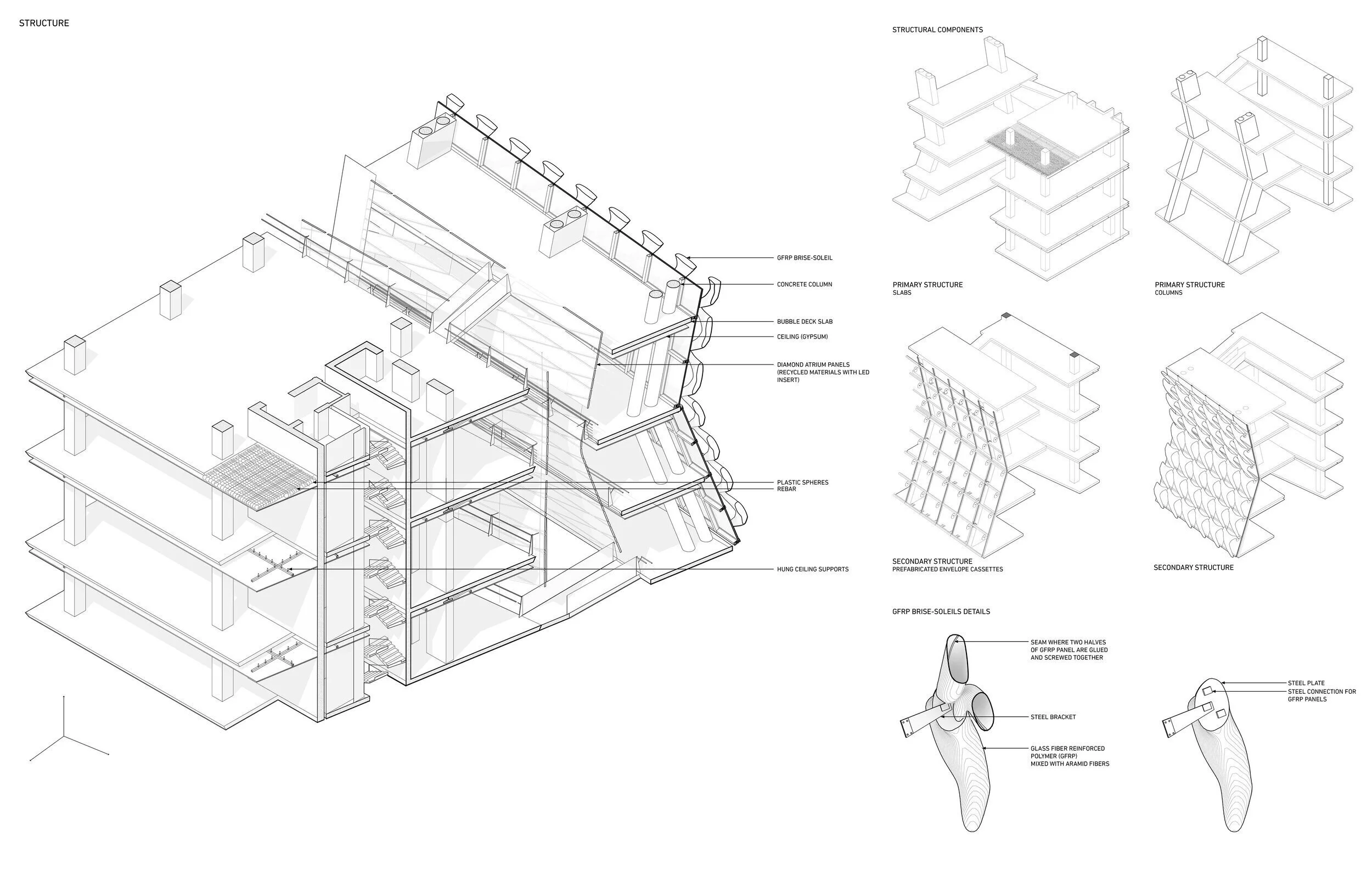

The Kolon One and Only is a research and development facility for one of the leading textile manufacturing companies in South Korea. The design features laboratories, administrative offices, and social spaces with a striking facade that demonstrates innovation, technology, and sustainability. One of the highlighting features of the building is the Brise-Soleil used for the facade. The design of the facade features an interconnected array of sunshades that form the monolithic, outer skin, analogous to woven fabric, a reference to Kolon’s research in textiles, as well as a symbol of collaboration between the company’s many departments. The units of the sunshade are parametrically shaped to balance shading and views and are made from fiber-reinforced polymer (FRP) using one of Kolon’s own high-tech fabrics, Aramid, to dramatically increase the material’s tensile strength. One of the most notable features of the design is the lack of a visible support structure, allowing the sunshade to seemingly float outside the glazed wall and providing clear views from the interior spaces.

For our transformation, we are proposing a material change from GFRP to ETFE. In the Kolon One and Only Tower, the GFRP panels had two major functions: sun-shading and cross-bracing the facade. We believe ETFE can address these two issues while bringing other additional benefits to the table. First, in terms of sun-shading and visibility, the ETFE will be covered in a custom frit pattern, thus allowing for an even higher degree of specificity than the GFRP offered. Second, the ETFE system is one of tension and as such makes it suitable to function as cross-bracing on the diagonal of the curtain wall. The additional structural benefits of ETFE are in regards to the wind. The lightweight quality of the material and its ability to deform under live load make it particularly suited to dampening wind. This is especially an asset as the Kolon Tower is located in an area prone to monsoons. ETFE also brings with it a higher degree of sustainability than GFRP. Where GFRP may collect dust and need to be cleaned, ETFE is non-stick and self-cleaned by rain.

Our proposed change utilizes ETFE in two major ways. First, there are be double-layer inflated ETFE panels where there was originally GFRP. Second, there will be an additional single-layer ETFE system that sits behind the inflated panels. These are outfitted with frit to control and harness the sun as well, thus taking material advantage of spaces that were completely empty in the original building.

When this system meets the corner, the whole setup transitions to a single-layer ETFE patterned with the shape of the front facade. In the current building, this facade is totally solid GFRC. The single-layer ETFE allows for controlled light where it was originally monolithic. The transition of the frits from the front to the side facade highlights the curvature of the inflated ETFE and the flatness of the single-layer ETFE.

In collaboration with Srimoyee Sinha, Irvin Shaifa and Christina Griggs.